A Shift in Perspective

Before founding MiCOM Labs, I spent many years working as a regulatory compliance engineer. My responsibilities spanned global approvals across RF/Wireless, EMC, safety, certification pathways, documentation repositories, and cross-functional coordination required to keep complex product programs moving forward.

From that vantage point, I had a clear view into how compliance was perceived inside most organizations. Rarely was it seen as an integral part of product development. More often, it was treated as a hurdle – something to be dealt with later, once the “real work” of engineering was finished.

Compliance was viewed as friction on the critical path to launch. It was seen as slowing momentum at exactly the moment when engineering teams and executives were under the most pressure to deliver.

Over time, I watched the same pattern repeat itself.

It usually began with good intentions. Teams would assume they could address regulatory requirements once designs were stable. Schedules were aggressive, optimism was high, and early risks were often downplayed.

Then reality set in.

A test failure surfaced that no one expected. A redesign became unavoidable. Timelines slipped, and pressure from leadership intensified. Customers began asking uncomfortable questions about delivery dates. Revenue projections quietly moved to the next quarter — and then the one after that.

What stood out most was not how often this happened, but how preventable it usually was.

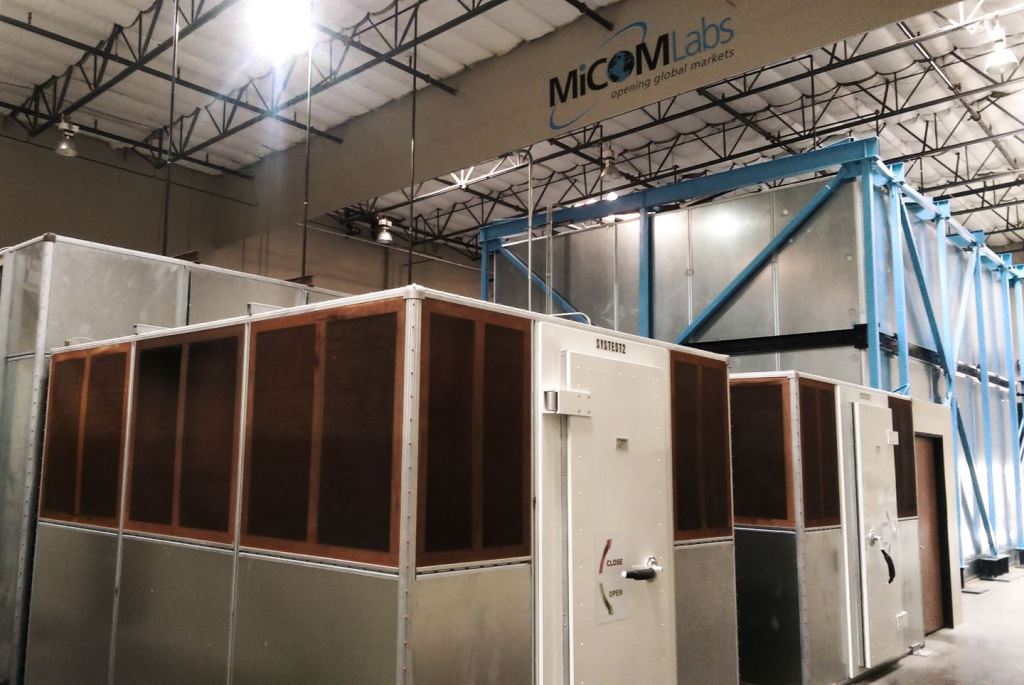

Those experiences shaped the philosophy behind MiCOM Labs. I didn’t set out to create another test lab. I set out to build the partner I wished engineering teams had earlier — one that could help manufacturers avoid the traps I saw every day by integrating compliance into the product journey from the start.

Compliance Is Not a Checkpoint – It Is a Business Strategy

When compliance is treated as a late-stage checkpoint, it behaves exactly like one. It becomes a gate that can stop progress at the worst possible moment, when options are limited and costs are high.

But when compliance is integrated early, something very different happens.

Engineering decisions are informed by regulatory realities rather than surprised by them. Risk is reduced instead of discovered late. Launch milestones become predictable rather than aspirational. Go-to-market planning becomes confident instead of hopeful. Costs remain stable rather than ballooning at the end of the program.

The same requirements exist either way. What changes is when — and how — they are addressed.

Treat compliance like a roadblock, and it will slow everything down.

Treat it like a core engineering pillar, and it accelerates the entire program.

When Compliance Goes Wrong, the Impact Compounds

Most organizations underestimate how far the impact of missed compliance timelines extends.

It is rarely just about a delayed certification or a failed test report. The consequences ripple outward, affecting financial performance, operational stability, internal culture, and customer relationships.

Over time, the same failure modes appear again and again. Revenue is pushed out. Engineering costs rise unexpectedly. Operations are forced into reactive mode. Internal trust erodes. Clients begin to question reliability.

Each of these outcomes feeds the next, turning what started as a technical issue into a business-wide problem.

The Financial Cost of Missed Compliance Timelines

The most immediate and visible impact of compliance delays is lost revenue.

A single missed quarter does not simply dent short-term performance — it can permanently alter the trajectory of a product line. Seasonal or high-demand sales windows close. Purchase orders are deferred or canceled and often do not return in full. Competitors gain shelf space and market share while your product sits uncertified.

Delayed certification leads to delayed launch.

Delayed launch leads to delayed invoicing.

Delayed invoicing leads to delayed cash flow.

In many cases, that lost momentum is never fully recovered. The financial consequences are immediate, measurable, and often far more severe than initially anticipated.

Late Compliance Fixes Drive Engineering Costs Up Fast

What often surprises leadership is how expensive compliance problems become when they are discovered late.

Late-stage changes trigger additional test cycles, redesign efforts, component substitutions, expedited lab fees, and extended debugging under intense time pressure. What could have been a modest design adjustment early in development becomes a full-scale engineering emergency.

These situations are not the result of poor engineering. They are the result of late engineering.

By the time compliance issues surface, the cost of fixing them has already multiplied — and those costs frequently reach six figures.

Operational Disruption Becomes Inevitable

When compliance timelines slip, operational plans slip with them.

Inventory sits idle in warehouses. Supply chain timing breaks down. Quarterly forecasts lose credibility. Teams across the organization are forced into reactive mode, constantly adjusting plans based on shifting certification dates.

Instead of executing a coordinated launch, organizations find themselves managing uncertainty. The ripple effects touch every department, from procurement and manufacturing to sales and finance.

The Hidden Cost: Culture and Morale

Missed compliance deadlines do not only affect the balance sheet. They take a real toll on the people doing the work.

Engineering teams experience burnout as they are pulled into repeated fire drills. Tension grows between product teams, quality, and management. Re-planning cycles become the norm rather than the exception. Confidence in internal schedules erodes.

Over time, a culture of uncertainty takes hold. Teams stop trusting timelines, and motivation suffers. When compliance feels unpredictable, morale inevitably declines.

How Compliance Delays Affect Your Clients

The impact does not stop at your organization.

Your clients feel the effects of missed compliance timelines just as acutely. Their product integrations stall. Their revenue timelines slip. Their partner commitments break. Their market launches move.

In the worst cases, they are forced to seek alternative suppliers — not because your technology failed, but because your delivery became unreliable.

Compliance delays do not just disrupt your roadmap. They can directly damage someone else’s business and permanently alter the relationship.

What Successful Compliance Actually Looks Like

Organizations that consistently get compliance right share a common approach.

They design for compliance at the architecture stage. They integrate regulatory checkpoints throughout R&D rather than deferring them to the end. They use pre-compliance testing to surface issues early, when solutions are still flexible. They work with partners who advise and collaborate, not just test and report failures.

Most importantly, they treat regulatory requirements as predictable milestones rather than unknown risks.

Predictability — not speed — is the real competitive advantage.

Why I Founded MiCOM Labs

After years of witnessing preventable delays, unnecessary redesigns, and product launches derailed by last-minute compliance failures, I set out to build a lab that operated differently.

MiCOM Labs was designed to be collaborative, transparent, and engineering-focused. Its purpose is to reduce risk early, provide clarity throughout development, and help manufacturers move forward with confidence.

Compliance does not have to be a bottleneck. When done right, it becomes a strategic enabler.

Final Thoughts

Compliance done well protects revenue, strengthens partnerships, reduces risk, and builds organizational confidence. It improves engineering efficiency and supports a healthier internal culture.

Compliance done poorly does the opposite.

Getting it right is not simply about passing a test. It is about building a system where failure is unlikely because the pathway has been engineered from the very beginning.

Gordon Hurst

Founder, President, CEO MiCOM Labs